- Sheet Material

- Boat Kits

- Jet Ski

- Cooler Pads

-

Hzsharks Southwest Cooler Pad for Yeti Tundra 45

Hzsharks Southwest Cooler Pad for Yeti Tundra 45

$399.86Original price was: $399.86.$92.99Current price is: $92.99. -

HZSHARKS Yeti Roadie 24 Cooler Mat

$20.99 – $24.99Price range: $20.99 through $24.99

HZSHARKS Yeti Roadie 24 Cooler Mat

$20.99 – $24.99Price range: $20.99 through $24.99

-

Hzsharks Cooler Cushion for Yeti Tundra 45

Hzsharks Cooler Cushion for Yeti Tundra 45

$69.99Original price was: $69.99.$55.99Current price is: $55.99.

-

- Fish Rulers

-

40" EVA Foam Fish Ruler for Boats

40" EVA Foam Fish Ruler for Boats

$38.99Original price was: $38.99.$21.99Current price is: $21.99. -

100cm Fish Ruler EVA Foam for Boats - Fish Measuring Stick

$19.99 – $23.99Price range: $19.99 through $23.99

100cm Fish Ruler EVA Foam for Boats - Fish Measuring Stick

$19.99 – $23.99Price range: $19.99 through $23.99

-

Fish Ruler for Boats 48" EVA Foam Fish Measuring Board with Self-Adhesive Backing

Fish Ruler for Boats 48" EVA Foam Fish Measuring Board with Self-Adhesive Backing

$38.99Original price was: $38.99.$25.99Current price is: $25.99.

-

- Boat Nameplate

- Dash Pockets

- Tools

A Comprehensive Guide to Eva Foam Boat Flooring: Addressing Your Frequently Asked Questions

Are you contemplating an upgrade to your boat’s flooring but unsure of how to proceed? Consider EVA foam boat flooring as an excellent option! This adaptable and resilient material is favored by many boat enthusiasts, yet numerous questions remain. To address this, we have developed this comprehensive guide, answering all your FAQs about EVA foam boat flooring. We provide comprehensive support from installation to maintenance, allowing you to focus less on research and more on enjoying the water while standing on a stylish and comfortable floor. Let’s get started!

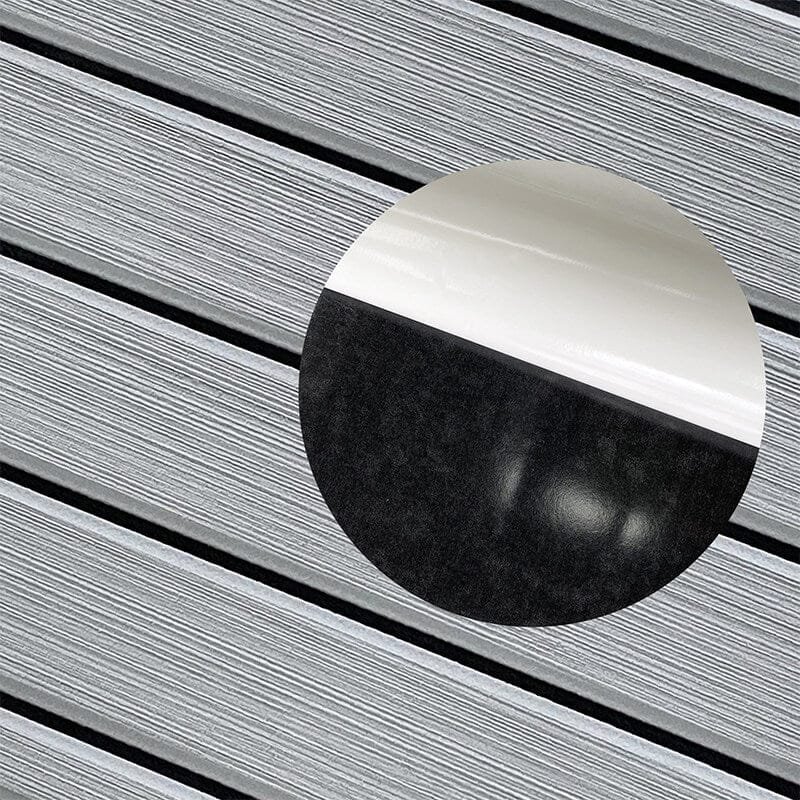

What is EVA foam boat flooring?

EVA foam boat flooring is a type of synthetic material made from ethylene-vinyl acetate (EVA) foam.

This robust, lightweight, and easy-to-maintain material has gained popularity among boat owners seeking to enhance their vessel’s flooring affordably.

A key benefit of EVA foam boat flooring is its slip-resistant nature, making it particularly suitable for wet conditions commonly found on boats. It also offers cushioning, which can alleviate fatigue during extended periods spent on the water.

Available in a wide range of colors and designs, EVA foam boat flooring allows for customization of your vessel’s aesthetic while ensuring practicality. Furthermore, as EVA foam is non-absorbent and resistant to UV rays and chemicals, it demands minimal upkeep and can endure for years with appropriate care.

EVA foam boat flooring represents an excellent choice for those in search of an economical yet high-quality solution to enhance both the safety and appearance of their vessels.

Related products: EVA Foam Boat Flooring

Jet SKi Mat Kits

How is EVA foam boat flooring installed?

The installation of EVA foam boat flooring is an uncomplicated process that can be accomplished by anyone possessing basic DIY abilities. The initial step involves cleaning and preparing the area of the boat where the foam will be applied.

Subsequently, measure and cut the EVA foam sheets to match the dimensions of your boat’s floor, utilizing a sharp utility knife or scissors. It is crucial to ensure that each piece fits tightly against its neighboring pieces without leaving any gaps.

Once all pieces are cut, apply a marine-grade adhesive to one side of each sheet and carefully position them on the boat’s floor. Make sure to press down firmly on each sheet to guarantee proper adhesion to the surface.

After all pieces are installed, use a roller or a flat object, such as a board or tile spacer tool, to apply even pressure across the sheets. Allow adequate time for the adhesive to cure before testing the new flooring.

The installation of EVA foam boat flooring does not necessitate specialized tools or professional expertise, yet it offers significant benefits, including enhanced comfort underfoot and increased safety by reducing slipping hazards on board.

What are the benefits of EVA foam boat flooring?

EVA foam boat flooring has gained significant popularity among boat enthusiasts due to its many advantages. Primarily, it offers exceptional traction, even in wet conditions, enhancing safety for individuals on board. This flooring type is also remarkably durable and resistant to damage, reducing the frequency of replacements compared to conventional boat flooring materials.

Another notable advantage of EVA foam boat flooring is its outstanding comfort. It provides cushioning that alleviates fatigue during extended periods spent on the water, which is particularly advantageous for those engaged in long fishing trips or leisurely cruising.

Moreover, this material is non-absorbent, eliminating concerns about mold or mildew developing in your boat’s carpeting or upholstery. In the event of spills, cleanup is straightforward—simply use soap and water.

One of the most appealing aspects of EVA foam boat flooring is its design versatility. It is available in a wide range of colors and patterns, allowing you to personalize your deck to suit your tastes.

Overall, there are numerous advantages to choosing EVA foam boat flooring over other materials typically used in boating.

Are there any disadvantages to EVA foam boat flooring?

EVA foam boat flooring offers numerous advantages; however, it is important to acknowledge some potential drawbacks associated with its use. One concern is that it may not possess the same level of durability as alternative materials such as teak or fiberglass. Although it can endure regular usage and exposure to water, it may deteriorate more quickly over time.

Another issue to consider is that the foam’s surface can become slippery when wet, which may create safety risks for individuals on the boat, particularly if they are moving swiftly or wearing wet footwear.

Furthermore, EVA foam boat flooring might not be ideal for vessels subjected to extreme weather conditions. Prolonged exposure to high temperatures or direct sunlight could lead to heat absorption, making the surface uncomfortable to walk on.

Although installing EVA foam boat flooring can be a straightforward process using adhesive glue, errors during installation may result in bubbles or an uneven surface.

Despite these potential disadvantages, it is essential to balance them against the many benefits of EVA foam boat flooring when deciding whether to utilize this material for your boat.

How long does EVA foam boat flooring last?

EVA foam boat flooring represents a robust and enduring choice for boat owners. The longevity of this flooring can fluctuate based on several factors, including the material’s quality, usage frequency, exposure to sunlight and water, and the maintenance it receives.

Typically, premium EVA foam boat flooring can endure for a period ranging from 5 to 10 years when properly maintained. Regular cleaning with mild soap and water is essential to avoid the accumulation of dirt or stains that could diminish its durability over time.

Additionally, the flooring’s lifespan is influenced by exposure to severe weather conditions. If you often navigate in regions with high UV radiation or saltwater exposure, the EVA foam may deteriorate more quickly compared to calmer environments.

By choosing high-quality EVA foam boat flooring, you can be assured of its resilience against wear and tear for an extended duration.

How much does EVA foam boat flooring cost?

One of the frequently asked questions regarding EVA foam boat flooring is its cost. The answer varies based on several factors, including the dimensions of your boat and the specific type of EVA foam selected.

Typically, the price of EVA foam boat flooring ranges from $30 to $100 per square meter. Although this may appear costly at first, it becomes a more appealing option when compared to high-quality marine carpeting, which can be even pricier.

The overall cost is also influenced by whether you decide to install the flooring yourself or hire a professional. While self-installation is feasible, many individuals prefer to engage professionals, which can increase the total expense of the flooring.

It is important to recognize that while some brands may carry a higher price tag, they often provide additional advantages such as enhanced durability or UV resistance. If you intend to use your boat regularly and desire flooring that will endure, investing in a premium brand could be worthwhile.

Although there are less expensive alternatives available for boat flooring, EVA foam stands out as an excellent option for those seeking an aesthetically pleasing solution that delivers exceptional comfort and traction.

Can I install EVA foam boat flooring myself?

One of the notable advantages of EVA foam boat flooring is its accessibility for installation, allowing individuals without professional experience to undertake the task. Many boat owners opt to install their own EVA foam flooring due to its straightforward nature, which does not necessitate specialized tools or equipment.

To begin the installation process, the first step is to accurately measure the area designated for the foam. This ensures that you acquire an adequate amount of material for the project. After obtaining your measurements, you should order the EVA foam boat flooring from a reliable supplier.

Upon receiving your order, it is essential to thoroughly review the installation instructions before proceeding. The typical installation process includes cleaning and preparing the boat’s surface, applying adhesive to both the floor and the underside of the foam, and then carefully laying down the foam sheets.

Taking your time with each phase of the installation is crucial to ensure a proper fit and an aesthetically pleasing result. If you encounter any uncertainty or discomfort during the process, do not hesitate to seek assistance from a professional.

Embarking on the installation of EVA foam boat flooring as a DIY project can be a rewarding experience, provided you adhere to the correct guidelines and exercise caution throughout each step.

Where can I buy EVA foam boat flooring?

In conclusion, EVA foam boat flooring is a favored option among boat owners due to its resilience, comfort, and straightforward installation process. Although there are some drawbacks, such as the risk of discoloration and challenges in stain removal, it remains a worthwhile investment for any boating enthusiast.

If you are considering acquiring EVA foam boat flooring, numerous online retailers provide this product. It is advisable to investigate the reputation of the company and examine customer reviews prior to making a purchase. Notable retailers include Amazon, Overton’s, and Hzsharks.

Furthermore, consulting with fellow boaters or visiting local marine supply stores can yield valuable recommendations for sourcing high-quality EVA foam boat flooring.

By dedicating time to thorough research and investing in EVA foam boat flooring, you can enhance your boating experience, ensuring greater safety and comfort while on the water.

Conclusion

EVA foam boat flooring presents a remarkable choice for any vessel aiming to reduce expenses while ensuring exceptional comfort and maintaining durability. Available in various sizes, it offers suitable options for any project you may be working on.